| ASTM Specification |

ASTM A789/ ASME SA789 |

|---|---|

| Standard | NF, JIS, GB, EN, AISI, ASTM, TOCT, SAE, DTD, DS, ASME, DIN, AMS, |

| Seamless Tubing Size | 3.35 milimeter To 101.6 milimeter OD |

| Size of ASTM A789 Welded Tubing | 6.035 milimeter To 152 milimeter OD |

| Bwg & Swg | 18 Swg., 14 20 Swg., Swg. Swg., 12 16 Swg., 10 Swg. |

| wall thickness of ASTM A789 Tubing | 0.0020" to 0.0220", (as per need available) |

| Tubing Schedule | SCH20, SCH40S, SCH80, SCH10, SCH60, SCH40, XXS, XS, STD, SCH120, SCH140, SCH80, SCH5, SCH10S, SCH160, SCH30 |

| Length | Cut and Standard length , Single Random, Double Random Pipe |

| Finish | NO.1, BA (Bright & Annealed), 2B, AP (Annealed & Pickled), Polished, MF, HL, NO.4, Mirror finish, BA, 8K etc |

| End | Plain End, Beveled End, Treaded Pipe, Screwed ends |

| Form | Hydraulic, Rectangular, Coiled, Square, Hollow, Round, Straight Pipes/tubes, “U” Shape, Pan Cake Coils, Boiler, LSAWetc. |

| Application | Dairy Pipe, Oil Pipe/tube, Gas Pipe/tube, Fluid Pipe/tube, Boiler Tube, Heat exchanger Tube |

| Type | Seamless /ERW/ EFW / Welded / Fabricated /CDW /DOM/CEW ASTM A789 Pipe |

| Marking | Heat No. (Or as per need.), Thickness, OD, Grade, Standard Length |

| Value Added Service | Expansion and Draw as per needed Length and Size, , Polish (Comilimeterercial and Electro), Machining, Pickled and Annealed Bending Etc. |

| Specialize in |

|

| Test Certificate |

|

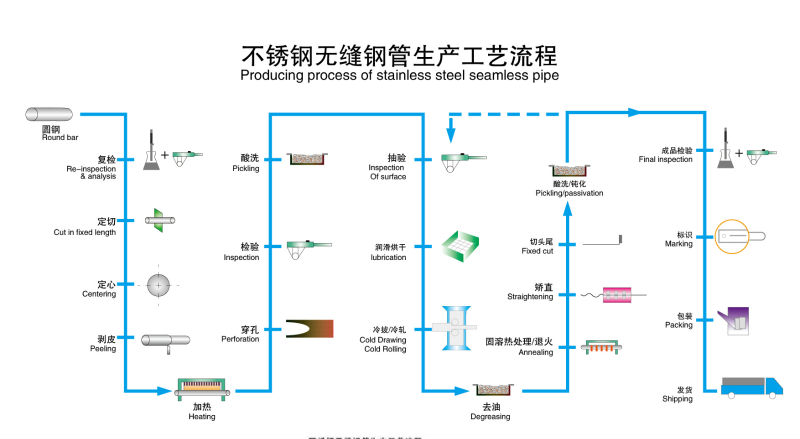

| ASTM A789 Tubing manufacturing Technique | Cold drawn, hot drawn, bright annealed, solid solution, hot extruding |

| ASTM A789 Tubing O.D. (in.) |

Wall Thickness of ASTM A789 Tubing (inches) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0.028 | 0.035 | 0.083 | 0.049 | 0.065 | 0.095 | 0.109 | 0.120 | |

| Working Pressure (psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 4000 | 2200 | 3000 | 4600 | ||||

| 1 | 2900 | 2200 | 3400 | 3900 | 4300 | |||

| Types | Out diameter | Length | Wall thickness |

|---|---|---|---|

| NB Sizes (available) | 1/8” ~ 8” | Upto 6 Meters | SCH 40 /SCH 10 /SCH 160/ SCH 5 / SCH 80 |

| ASTM A789 Seamless Tubing (as per need) | 5.00 milimeter ~ 203.02 milimeter | as per need | |

| ASTM A789 Welded Tubing (available + as per need) | 5.00 milimeter ~ 1219.02 milimeter | 1.00 ~ 15.00 milimeter |

| Grade | Hardness, Max Brinell | Yield strength, min., ksi [MPa] | Tensile strength, min., ksi [MPa] | Elongation in 2 in., or 50mm, min, % |

| S32205 | 290 | 70 [485] | 95 [655] | 25 |

| S31803 | 290 | 65 [450] | 90 [620] | 25 |

| S32550 | 297 | 80 [550] | 110 [760] | 15 |

| S31500 | 290 | 64 [440] | 92 [630] | 30 |

| S31260 | 290 | 65 [450] | 100 [690] | 25 |

| S32520 | 310 | 80 [550] | 112 [770] | 25 |

| S31200 | 280 | 65 [450] | 100 [690] | 25 |

| S32304 | 290 | 65 [450] | 100 [690] | 25 |

| S32001 | 290 | 65 [450] | 90 [620] | 25 |

| S32760 | 300 | 80 [550] | 109 [750] | 25 |

| S32750 | 310 | 80 [550] | 116 [800] | 15 |

| S32950 | 290 | 70 [480] | 100 [690] | 20 |

Standard Specification:

ASTM A213/A213M - 11a: Standard Specification for Seamless Ferritic and Austenitic Alloy - Steel Boiler, Superheater, and Heat - Exchanger Tubes

ASTM A269 - 10: Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

ASTM A312/A312M - 12: Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

ASTM A789/A789M - 10a: Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

ASTM A790/A790M - 11: Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

EN Standards

EN 10216 - 5 Welded Stainless Steel Tube

EN 10216 - 7 Seamless Stainless Steel Tube

EN 10216 - 7 Seamless Stainless Steel Tube

German - Standards

DIN 17456 Seamless circular austenitic stainless steel tubes for general service

DIN 17457 Welded circular austenitic stainless steel tubes subject to special requirements

DIN 17458 Seamless circular austenitic stainless steel tubes subject to special requirements

DIN 17459 Seamless circular high - temperature austenitic stainless steel tubes

DIN 28180 - 85 Seamless steel tubes for tubular heat exchangers

DIN EN ISO 1127 Seamless stainless steel tubes (Dimensions and weights)

| Product Name | Executive Standard | Dimension | Steel Code / Steel Grade |

| Seamless Austenitic Stainless Steel Pipes | ASTM A312/A312M, ASME SA312/SA312M | OD: 1/4"~20" | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| WT: SCH5S~SCH80S | |||

| Seamless Austenitic Stainless Steel Tubing for General Service | ASTM A269, ASME SA269 | OD: 6.0~50.8mm | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Seamless Austenitic Alloy-Steel Boiler, Super Heater and Heat-Exchanger Tubes | ASTM A213/A213M, ASME SA213/SA213M | OD: 6.0~50.8mm | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| WT: 0.8~10.0mm | |||

| Seamless Duplex Stainless Steel Tubing for General Service | ASTM A789 / A789M | OD: 19.0~60.5mm | S31803, S32205, S32750 |

| WT: 1.2~5.0mm | |||

| Seamless Duplex Stainless Steel Pipes | ASTM A790 / A790M | OD: 3/4"~10" | S31803, S32205, S32750 |

| WT: SCH5S~SCH80S | |||

| Seamless Stainless Steel Mechanical Tubing | ASTM A511 | OD: 6.0~50.8mm | MT304, MT304L, MT304H, MT310, MT310S, MT316, MT316L, MT317, MT317L, MT321, MT321H, MT347 |

| WT: 1.8~10.0mm | |||

| Seamless Stainless Steel Tubes for Pressure Purposes | EN 10216, DIN 17456, 17458 | OD: 6.0~530.0mm | 1.4301, 1.4307, 1.4541, 1.4401, 1.4404, 1.4571, 1.4878, 1.4432, 1.4462 |

| WT: 0.8~34.0mm |

Application Field :

|

Industry |

Applications |

Industry |

Applications |

|

Chemical |

Heat Exchanger, Boiler |

Sugar |

Evaporators, Condensers, Driers |

|

Petrochemicals |

Condensers |

Automobiles |

Muffler Tubes Hydraulic Tubing |

|

Refineries |

General Piping |

Construction |

Architectural Furniture |

|

Fertilizers |

Pressure Vessels |

Pharmaceuticals, Dairy, Food & Beverages |

Machineries Process Piping |

|

Paper & Pulp |

Industrial Equipments |

Submersible Pumps |

Pump Casing Applications |

|

Engineering |

Machineries Instrumentation Tubing |

|

|

Competitive Advantage:

1. We offer you our best price with good quality of the materials.

2. We will deliver the materials strictly according to the the delivery date noted on the contract.

3. We also always have the huge ready stock for sell.

4. We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on

5.We have complete after - sale service to deal with the problems in time.

6. Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packing in bundles.

ASTM A789 Seamless Duplex Stainless Steel Pipe for General Service The high content of these elements in the ASTM A789 Seamless Tube makes its resistance superior to regular stainless steel. We are available in various dimensions, shapes, and sizes.